Dr. Zhenhua Li graduated from the University of Science and Technology Beijing with a PhD degree in 2022. Currently, he is an Associate Research Fellow at the National Center for Material Service Safety Science of University of Science and Technology Beijing. His research areas include environment assisted cracking (corrosion fatigue, stress corrosion cracking, etc), fatigue and fracture of engineeing materials and structures, finite element simulation and life prediction. To date, he has published more than twenty papers in Corrosion Science, International Journal of Fatigue, Materials Science and Engineering A, etc,and served as a reviewer for numerous journals such as International Journal of Fatigue.

- “National Natural Science Foundation of China”, “Research on the mechanism of scratches on corrosion fatigue”, total fund 300000 RMB, 2025-2027.

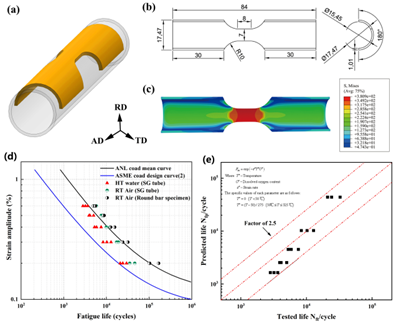

-Environmental fatigue plays an important role in safety design, operation, maintenance, safety assessment, life prediction and life extension assessment. Considering the effects of temperature, dissolved oxygen and strain rate on the corrosion fatigue performance, the environmental fatigue design model was established. Combined with advanced microscopic analysis and characterization, the influence mechanism of different factors on corrosion fatigue crack initiation and propagation was revealed and the corrosion fatigue damage mechanism model was established.

Fig.1.Corrosion fatigue behavior and life evaluation.

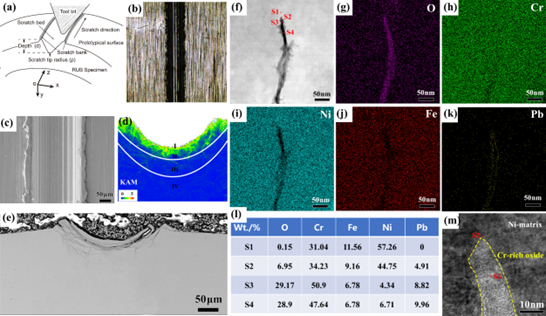

-In recent years, the failure of materials and components reported mainly comes from surface defects (scratches, dents, cracks, etc.). Systematic research has been conducted on the stress corrosion cracking and corrosion fatigue failure mechanisms induced by surface defects, as well as damage tolerance evaluation. The research mainly includes the influence of different defect types, depths, and environments on service failure behavior, as well as online detection of crack growth rates in materials containing defects, and establishment of corresponding life prediction models.

Fig.2. Stress corrosion cracking behavior and mechanism of scratched specimen.

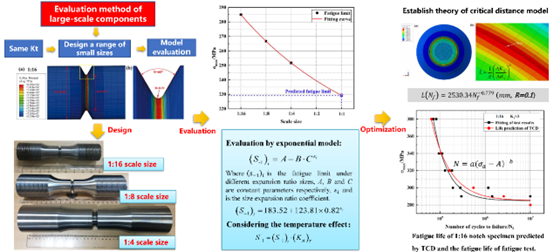

- With the increasing size and complexity of modern mechanical equipment structures, the evaluation of large-sized or full-size domain components has become particularly important. A series of studies on size and environmental effects were conducted on components such as main bolts, flanges, and main pipelines. The failure mechanisms of components in different size domains were analyzed, and a full-scale component life evaluation model was established.

Fig.3. Fatigue life prediction of main bolt based on temperature effect and size effect.

1. Z.H. Li, L. You, L. Wang, X.F. Zhao, Y. Su, Y.H. Lu, T. Shoji. Stress corrosion cracking behavior and mechanism in lead-containing caustic solution. Corrosion Science, 2025, 245, 112702.

2. Z.H. Li, Y.H. Lu, L. You, X.F. Zhang, L. Wang, D.H. Tian, W.D. Zhang, T. Shoji. Effect of temperature on corrosion fatigue behavior, Corrosion Science, 2024, 227, 111741.

3. Z.H. Li, Y.H. Lu, C. Hong, Y.G. Zhao, Y.M. Han, T. Shoji. Corrosion fatigue damage mechanism and life evaluation. Corrosion Science, 2023, 212, 110953.

4. Z.H. Li, X.Y. Wang, C. Hong, Y.H. Lu, T. Shoji. Fatigue crack initiation and propagation behavior. Materials Science and Engineering A, 2021, 811, 141090.

5. Z.H. Li, K. Han, T. Chen, H.S. Yang, P. Liu, Y.H. Lu. Fatigue life prediction of main bolt based on temperature effect and size effect. International Journal of Fatigue, 2021, 137, 105662.

6. Z.H. Li, Xinyu Wang, Junping Wang, Yonghao Lu, Tetsuo Shoji. High cycle fatigue behavior and numerical evaluation. International Journal of Fatigue, 2020, 137, 105662.

7. Z.H. Li, Y.H. Lu, C. Hong, Y.G. Zhao, W.D. Zhang, T. Shoji. Effects of foreign object damage on high-cycle fatigue behavior. Engineering Fracture Mechanics, 2023, 292, 109660.

8. Z.H. Li, C. Hong, Y.G. Zhao, Y.H. Lu, T. Shoji. Cyclic deformation behavior and cracking mechanis. Materials Characterization, 2022, 190, 111935.

9. Z.H. Li, Y.M. Han, Y.G. Zhao, S.L. Yang, Z.M. Zhong, Y.H. Lu. Thermal corrosion fatigue crack growth behavior and life prediction of 304SS pipeline structures. Engineering Failure Analysis, 2024, 160, 108224

10. Z.H. Li, X.Y. Wang, C. Hong, Y.H. Lu, T. Shoji. Effect of scratch depth on high cycle fatigue . Journal of Materials, 2022, 558, 153400.

1. Zhenhua Li, Yonghao Lu, Kun Han, Fan Feng. A test device and method suitable for the fatigue of thread missing teeth of threaded connections: China, 201911047772.X.

2. Xinyu Wang, Yakui Bai, Chen Sun, Ke Wang, Zhenhua Li, Tingguang Liu, Yonghao Lu. A fixture suitable for high-temperature and high-pressure water slow strain rate tensile testing of metal thin-walled tube specimens and its usage method: China, 202120189249.7.

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026